A Mexican company has developed a “jigsaw” brick that, it says, can halve the time required to build a wall.

Armed Omega says its “Block Armo” system can be assembled without using mortar. Rather, they are fitted together like pieces in a puzzle.

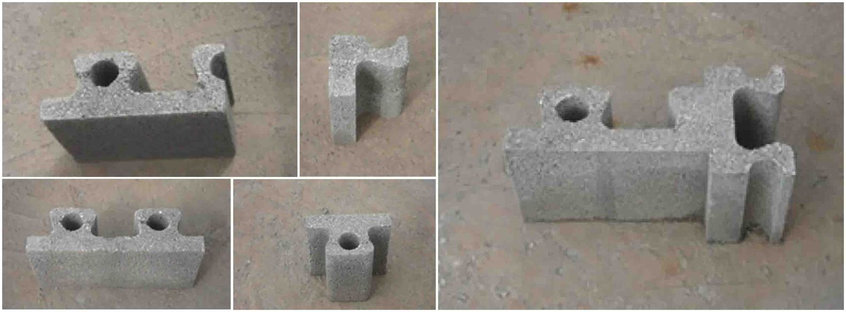

There are six shapes of block, each of which has a cylindrical internal space. Once a wall has been completed, steel rods are inserted into them every 80cm, followed by poured concrete. The result is a hybrid of traditional brick and reinforced concrete that can reproduce the decorative features of traditional brickwork.

The company has produced a video that illustrates how the system can be used to build a 25 square metre room in two hours.

Jorge Capistran, architect who invented the jigsaw blocks (picture courtesy of TechBA)

It points out that the blocks’ internal spaces can be used to fit mechanical, electrical and plumbing services.

As well as cutting construction time, the company says it reduces cost by 25%. One advantage of the system is that, as the blocks can be fitted together only one way, they can be assembled by relatively unskilled labour.

Armed Omega, which is based in the town of Puebla, 140km to the east of Mexico City, first announced its invention at the end of last year as an entry in Mexico’s National Entrepreneur Week.

It was designed by Jorge Capistrán (pictured), the founder and chief executive of Armed Omega, and is intended to make it easier to build high quality social housing.

Capistrán told the TechBA website that the system had been validated by Stanford University and the bricklayers’ union leader of California.

Five of the six available types of block (Armed Omega)

He added that this system was based upon “the principles of the geometry of the golden section, which allows change dimensions without losing its proportion”.

Image: How the bricks fit together (picture courtesy of National Council of Science and Technology)

Further Reading:

Comments

Comments are closed.

Wimpey developed something similar in the 80’s.

maybe once they get a grasp of Health and Safety they might be onto a winner.

Interesting design. It allows for grout filled reinforcement in vertical cells. I don’t see a means for grout and reinforcement in horizontal cells.

The wall system needs to stand up to horizontal forces, including wind and seismic. If not, we could see a lot of deaths similar to what happened in Haiti.

In the Haitian earthquake, many buildings came down on people because manufactured concrete block was substandard, it was sand with a small amount of cement for a binder.

Concrete block needs steel reinforcement in both directions. It adds ductility (or “stretchiness”) and weaves a basket to hold the block together, even as the concrete begins to fail. Unreinforced block walls have come down in pieces on school children. Partially reinforced could also come down, if not properly designed to hold together.

I hope this system can be developed to meet structural criteria.

Now if vertical holes for vertical steel reinforcing is being done then why not add horizontal ones for horizontal steel reinforcement as well! However vertical splice bars into the concrete footings are just as essential to prevent such walling from collapse in the event of an earthquake! in addition the roof structure must be anchored down securely to the main outer walls by securing the vertical wall steel reinforcement firmly to it! They should actually build a small “mock-up” house using this method and then subject to an assimilated earthquake to check its resistance to various intensities and then improve the system further before proceeding with any housing scheme using such a time and labour saving method!

what is their coefficient of keeping heat inside on winter time(with -25Celsius)?

where can we read more about tech details(website)?

can be made bigger(depth of total wall 35-40cm)?

are available for sale in Europe?

Please make a set of molds available for these blocks. Gardeners will be all over them. I know we’re small-fry, compared to construction companies, but we love making our concrete and hypertufa structures ourselves and this would allow people to build nice raised beds and other outdoor structures easily. We could build sheds and root cellars, all kinds of things. With your help, we could all change the world.

Any chance of getting small quantity molds made available for purchase?