After a narrow escape from the crash, Denmark’s second biggest contractor, MT Højgaard, vowed to go digital. With a modelling team in Vietnam and a new cost-centric BIM, it’s aiming for full launch in September.

On 25 August 2013, Pihl & Son, the third largest construction company in Denmark filed for bankruptcy. The news was not unexpected: the global crash struck while it was in the middle of an international expansion programme. It had borrowed on the book value of its assets and, although it never stopped making a profit, the deficits became overwhelming. Eventually, one of its main creditors, Danske Bank, appointed its own executive to chair the board, and she took the decision to end the firm’s credit. When it finally collapsed, it left debts totalling $2.5bn.

Most CEOs talk about BIM but most are not really that interested in it. Torben feels it in his heart– Ole Berard, head of Højgaard’s VDC modelling department

Denmark’s second biggest contractor, MT Højgaard, appeared set to follow it into the history books. Højgaard had followed a more conservative strategy. Apart from a big resort in the Maldives and a few other international one-offs – a joint venture hydroelectric scheme with Pihl in Panama, a cement factory in Buxton, UK – it had concentrated on the Scandinavian market.

But it still fell prey to bidding the wrong price at the wrong time, and in 2011 it made a loss of $50m. As credit drained from the system in the wake of the banking crisis, the firm’s position began to give cause for concern.Â

The results prompted chief executive Kristian May to fall on his sword, and in March 2012 the board appointed Torben Biilmann as his replacement. Biilmann had been vice president of the Danish arm of Swedish contractor NCC Construction, and had been credited with turning around its fortunes. When he arrived at his first day in his new job in November 2012, he brought with him the beginnings of a plan to do the same for Højgaard. Â

Fundamentally flawed

Biilmann believed that something fundamental had to change in the contracting business. As he told the Danish financial daily Børsen in October last year: “The problem in the industry is not that every company isn’t good enough. The problem is the way they are asked to tender. And when they do a project together, inefficiencies in structures and processes mean that everything they do is suboptimal.”

Biilmann plan was first to stop the losses and then to remodel the company around a process called virtual design and construction (VDC). The firm maintains that while other companies are working out how to use building information modelling (BIM) to make digital building fit into their existing practices, it will alter itself to fit into digital building.

“The difference between us and every other construction company in the world is that we have a CEO who is really, really dedicated to digital construction,” said Ole Berard, head of Højgaard’s VDC modelling department, in an interview with GCR.Â

“Most CEOs talk about BIM but most are not really that interested in it. Torben feels it in his heart, and he was that way from the day he arrived.”Â

Strengthening the defences

First, though, Højgaard acted decisively to stop losing money. It appointed a three-person project board to scrutinise every contract before it was signed, and every contract meeting had to have someone from the finance department present.

“In the past people got carried away and they really wanted to build their project,” said Berard. “It’s a typical engineering thing: people want to build cool buildings, so they get the director excited and he will sign off and we don’t care about the risk. We know it will also look good on our resumé.”

The aim was to take a severely professional approach, even if that meant cutting the firm’s turnover. Rolf Büchmann-Slorup, Højgaard’s VDC project leader, says it is expected that turnover in the short term will fall by a couple of billion kroner, or several hundred million dollars.Â

Once the risk management system had been put in place, the next step was to work out how the VDC system was going to work, and this is what Højgaard’s digital experts have been working on over the past couple of years.

They insist that this is not just about adopting BIM. Instead, it was about re-orienting the company and its processes around VDC – to create “rational construction projects”, as Biilmann told Børsen.

Biilmann decided to invest $15m in transforming the company. “It’s a huge sum for a construction company to spend,” said Berard. “Two years ago, we didn’t even own our own computers.”Â

New approachÂ

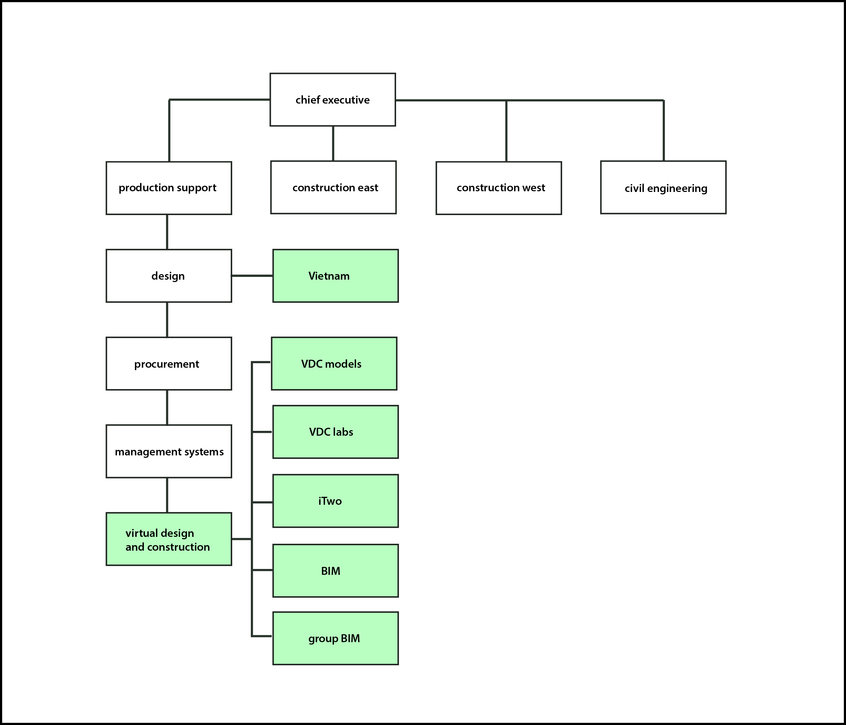

To create the organisational support structure for Højgaard 2.0, Biilmann added a VDC division, which controls five operational units pushing virtual design into all parts of the business. This amounts to 28 new people, but the headcount will grow to 40.

Højgaard’s table of organisation. New VDC departments coloured in green

Berard says: “We educate people in the construction divisions about BIM.”

The firm built a central database that all projects would add to and be informed by.Â

The company also created a “VDC lab” at its Copenhagen headquarters. This is a suite of rooms complete with a spiked “ideas ball” and modelling software to guide discussions with clients, suppliers and subcontractors.

Ole Berard in the “Ideas Room” area of the VDC lab suit (Source: GCR)

“We front-load our tender process so everyone is in the same room when we need them at the start,” said Büchmann-Slorup. The aim is to get everyone starting the job on the same page.

Højgaard wants to use its design software to produce the best possible tender. “On average when you construct a building you have 2.4 alternatives to each design decision, and then you select one, and that’s what you control,” said Büchmann-Slorup.Â

“We want to do as many as a 100 alternatives and we want to do it in a matter of hours instead of weeks. That is what the software enables us to do, and we will when we’ve built up the processes to make sure that it will work properly.”Â

Cost-control, and Vietnam

The approach is driven by software from the German firm, RIB. Biilmann signed a strategic agreement with RIB in October 2014 last year, and in exchange for a large part of the DK100 million, RIB will license and support its principal product: the iTwo application.

Berard says iTwo was chosen because it has something that its rivals lack: a thorough understanding of the cost process.Â

RIB started in the 1970s as German cost estimation software. It went public in 2006 and invested the money in developing VDC. Said Berard: “Now they have added a BIM module onto that and it’s a great piece of software. It’s more natural to a contractor to begin with the cost.”Â

Joakim Lockert, a BIM co-ordinator with Højgaard, says: “When we change the 3D model, we can monitor the quantities and the cash flow once the prices have been assigned, and we can see when we have to bill the client and when we have to pay our subcontractors. So we can take the 3D model and we can overlay the payment plan on top.”

Another key decision was to open a design department in Vietnam to handle the creation of 3D models. This employs about 50 Vietnamese draftspeople together with a Danish engineer and office manager.

Berard said Vietnam was picked over the more popular choice of India because Vietnamese employees stay in one job longer, whereas the Indian labour market encourages people to switch companies frequently, with the ultimate aim of getting a job in the Middle East, the US or Europe.Â

Where now?

The VDC teams have been rehearsing with dummy projects. Last month they also began to shadow live schemes.

The deadline for the employing VDC on actual projects is September this year. At first it will only be applied to tenders – and the VDC lab is partly intended to dramatise Højgaard’s new approach for the benefit of clients.

The firm wants to have VDC fully operational by 2017. A key goal is to improve the company’s bidding. “The end result is to increase our hit rate on bids,” said Büchmann-Slorup. “We now win one in five, and we currently have a target of one in four. We can see that our business partners in America, DPR Construction, can reach three in four.”Â

It’s too early to tell if it will work, but Büchmann-Slorup believes the company is now secure. “We just came out with our 2014 results and they’re very positive. We did lose some legal disputes and that made them look worse than they were, but the main engine of the company is running really well and we have our cash flow under control so we are a really solid firm now.

Top image: Joakim Lockert (left) and Rolf Büchmann-Slorup are among the planners of Højgaard’s new system (Source: GCR)

Comments

Comments are closed.

This is very imaginative and collaborative. How do you recover the abortive design costs and delays caused as a result of indecision or reluctance to commit to the project?

This is the way forward they have the vision of the future