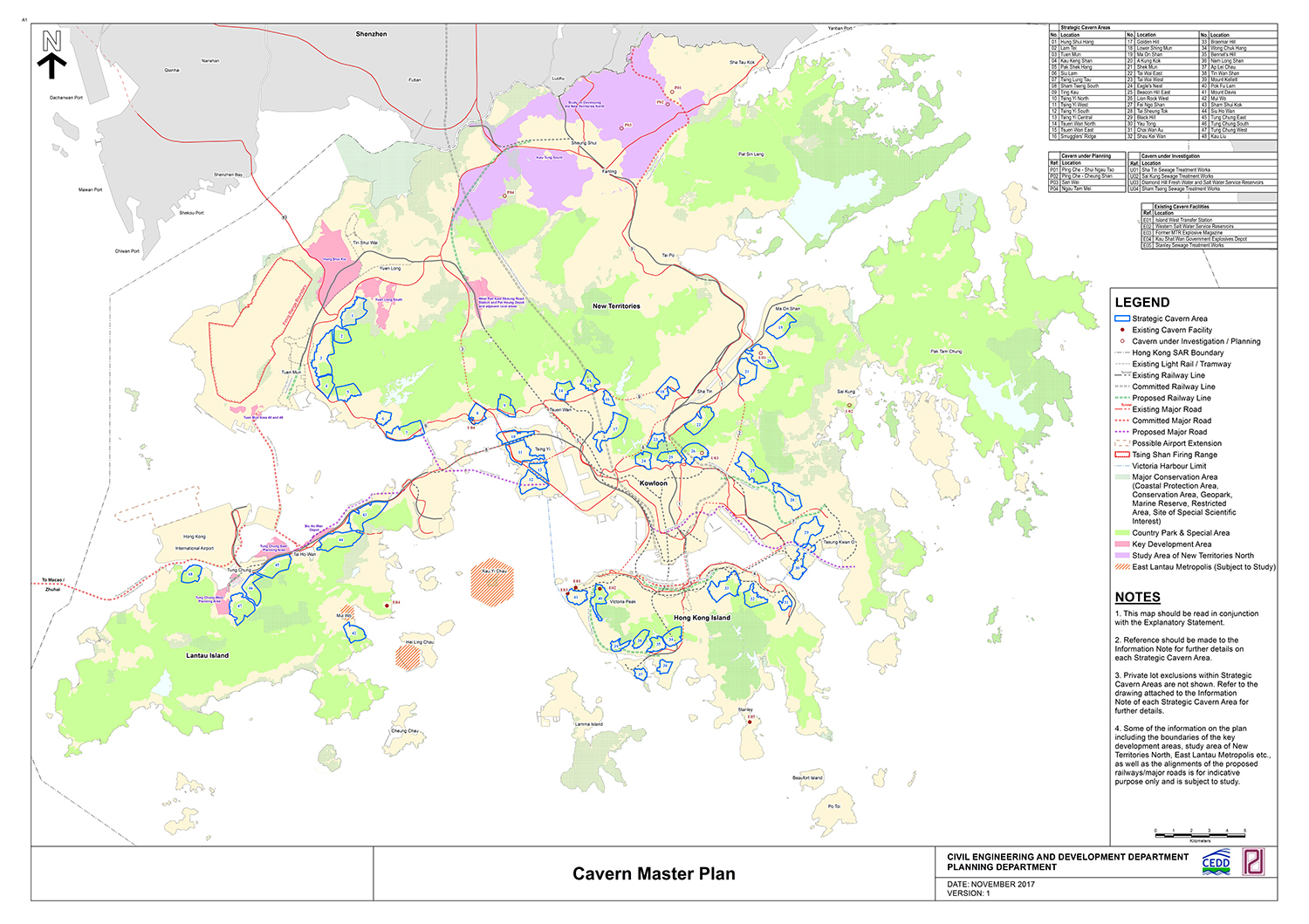

Hong Kong has an ambitious plan to ease the pressure on land supply by creating a network of caverns burrowed into the sides of hills. This has the potential to create more sustainable and future-ready communities.

A recent report commissioned by the government’s Geotechnical Engineering Office noted that 48 “strategic cavern areas” had been identified. These could in future house government departments, sewage treatment works, warehousing and logistics centres, server farms and the storage of such items as archives and wine.

The problem is that subterranean construction usually costs between two and three times as much as work on the surface. So, to make this construction programme, successful, its planners should harness the power of digital engineering. In this article, two executives at international engineering and design consultancy Aurecon list five ways this might be done.

3D geological modelling

Understanding geological conditions is a key to the successful delivery of underground construction.

Unfortunately, this typically relies on interpretation based on 2D sections with a small amount of 3D visualisation, which makes the process time consuming and often leads to a lack of clear communication. Fortunately, there is software that can speed up construction and deliver higher quality work. At Aurecon we use “Leapfrog”, which offers three significant benefits.

Firstly, it enables real time updates to the visualisation, which gives greater efficiency and accuracy and saves substantial time in drafting.

Secondly, it improves collaboration through easier sharing, because having geological data available from a centralised and auditable environment makes it easier to bring project teams together, helping them stay connected and enhancing decision making.

Finally, using a software package such as Leapfrog facilitates compatibility with different parts of the design. Being compatible with BIM, GIS and other analytical software programs makes for easier and faster overall project management.

In combination, the benefits of 3D geological modelling bring tangible improvements in the engineering process, including offering better risk management of geotechnical issues, which offers increased safety to site personnel.

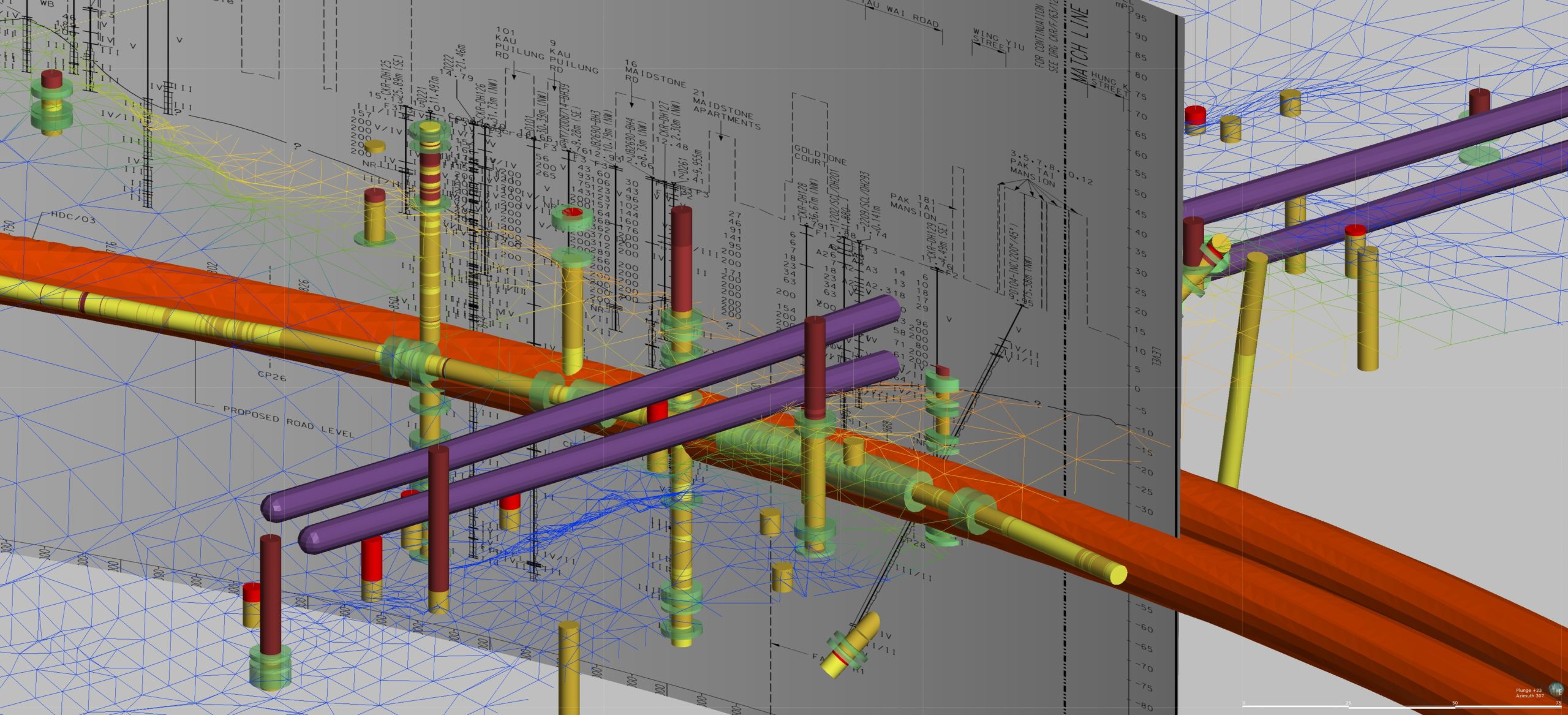

GIS for blasting assessment

Using a geographic information system (GIS) for the blasting assessment report avoids the need to manually engineer the vibration contours when designing the blast plan for underground construction. It also delivers accurate 3D visualisations of the blast plumes and vibrations limit on structures above ground.

At the construction stage, these detailed graphic representations are helpful in enabling stakeholders to understand the effects of the blasting performance and builds trust among those who might be affected by the work. Most stakeholders are unfamiliar with the drill and blast process and that uncertainty can raise concerns among communities and building owners.

Having these accurate and detailed visualisations goes a long way to alleviating worries, allowing work to proceed to schedule.

Laser scanning excavation

Once blasting work has completed, laser scanning of the excavation can be employed to map the cavern profile and detect areas of potential overbreak and underbreak. This is done by taking a scan before and after the lining of the cavern has been applied.

To bring further efficiency to this stage of the process, developers should also consider using sprayed concrete to create the cavern’s permanent lining, as opposed to in situ concrete.

By comparing the point cloud data at various points in the cavern before and after the lining is applied, areas of weakness or over-fortification can be easily identified, allowing adjustments to be made. This will then lead to greater efficiency, especially in optimising how much concrete is used in the project.

At Aurecon, we have developed a bespoke program for this.

Digital rock mapping

Following excavation, another way digital tools can help the construction progress is through digital rock mapping. During construction of the cavern, the rock face of the subterranean space must be mapped regularly by a geologist to record data such as material type, joint count, water characteristics, roughness and alteration.

At present, this is typically recorded using a pen and paper. However, with new customisable apps, it is possible to record the data via a smart device. This improves accuracy, speed and safety, and also means data can be uploaded in real time improving ground support optimisation.

Field Force application

A further option for digitising work during construction is to use a device-based app for site inspections. Ideally this app will take the form of an online database that allows users to create their own forms for repetitive data capture. Incorporating this customisation allows onsite personnel to tailor the form to the project.

Data collected from the form should be automatically uploaded to an online portal where it can be easily accessed by other stakeholders, reducing work duplication and the risk of errors.

Bold vision needs bold thinking

Looking to move more infrastructure underground is not new, but the scale of Hong Kong’s ambition is unprecedented. To truly reap the rewards of this ambitious effort will require new thinking and, more importantly, new technology. With a wholehearted approach to digital engineering, Hong Kong has an opportunity to create a position as a world leader in moving infrastructure underground.

- Ray Chan is Aurecon’s director of operation in Greater China; Jason Chin is technical director for tunnelling in Greater China

Top image: Hong Kong’s strategic caverns masterplan lists up to 48 sites for excavation (Government of Hong Kong)

Further reading: