5 March 2014

The term “wiki” is the indigenous Hawaiian term for fast, or quick. It has also come to mean “open source”, that is, provided by everybody and available to everybody, as Wikipedia is.

Now a team of young designers has applied the concept to home-building, and they claim it will allow anybody – even those untrained in design or construction skills – to build dwellings for themselves in just days.

The project, WikiHouse, calls itself an “open source construction system”. Its aim is to make it possible for anyone to design, adapt, share, and download plans for houses that are low-cost, high-performance and suited to local needs.

How it works

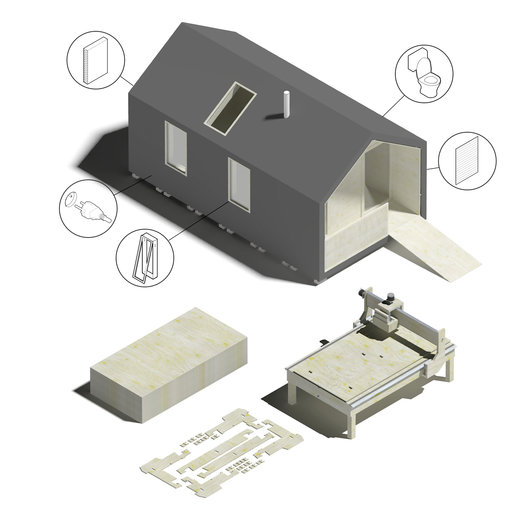

There is a WikiHouse plugin for the design software Google SketchUp that enables users to generate cutting files for components, including all necessary joints.

Using a CNC machine (computer numerically controlled), the house parts can be cut from a standard sheet material like plywood and the main structure assembled in about a day without the need for construction craft skills.

A WikiHouse plugin for the design software Google SketchUp that enables users to generate cutting files for components, including all necessary joints (WikiHouse)

WikiHouse says it can “radically lower the thresholds of time, cost, and skill and to put the capability to make generous, healthy, secure housing into the hands of users.”

Homes for the 100%

There is a big social idea behind the WikiHouse concept – buildings for the masses.

One of the founders, 30-year-old Alastair Parvin of London-based design studio 00 (you say “zero zero”), told last year’s TED conference in Long Beach, California that the WikiHouse experiment has potential to disrupt the way we make housing and cities.

“The open secret is that in reality almost everything we today call architecture is actually design for the 1%,” he said.

“The challenge facing the next generation of architects is how, for the first time, we will make our client not the 1% but the 100% – to radically democratise the production of architecture.”

“A new building,” he added, “is about the most expensive solution you can think of to almost any given problem.”

He also argued that we need to rethink the way we make and procure cities, shifting from top-down, speculative development to development by “the many with a bit, making houses not just as assets to sell but as places to live. What would it mean to give citizens a Right to Build?”

Using a numerically controlled cutting machine, the house parts can be cut from a standard sheet material like plywood (WikiHouse)

“The reality is that the fastest growing cities globally are not formally developed cities but ‘self-made’ cities. So if we’re serious about tackling problems like urbanisation, climate change and inequality, we need to develop solutions not just to construction but also off-grid sustainable infrastructure, and to put them into a democratic commons – a kind of Wikipedia for ‘stuff’.”

Small experiment

WikiHouse was launched in September 2011 by 00, Espians, Momentum Engineering, and Beatrice Galilee, according to Designing Buildings Wiki, and won the TED Cities2.0 Award in 2012.

So far, this building method designed for the masses has yet to be taken up by them. According to Popular Science magazine the only WikiHouse in the UK is a walker’s shelter in Fridaythorpe, England.

The challenge of getting one’s hands on a CNC cutting machine may be a challenge, not to mention the land on which to build a house.

However, WikiHouse admits it is a “small experiment continuously under development”, and says there is a growing community of teams involved, including one in New Zealand working on solutions to post-earthquake housing, and one in Brazil applying the concept to the slums of Rio de Janeiro.

Meanwhile they’re seeking collaborators, funders, and of course people who want to make a WikiHouse for themselves.

For more information visit: www.wikihouse.cc