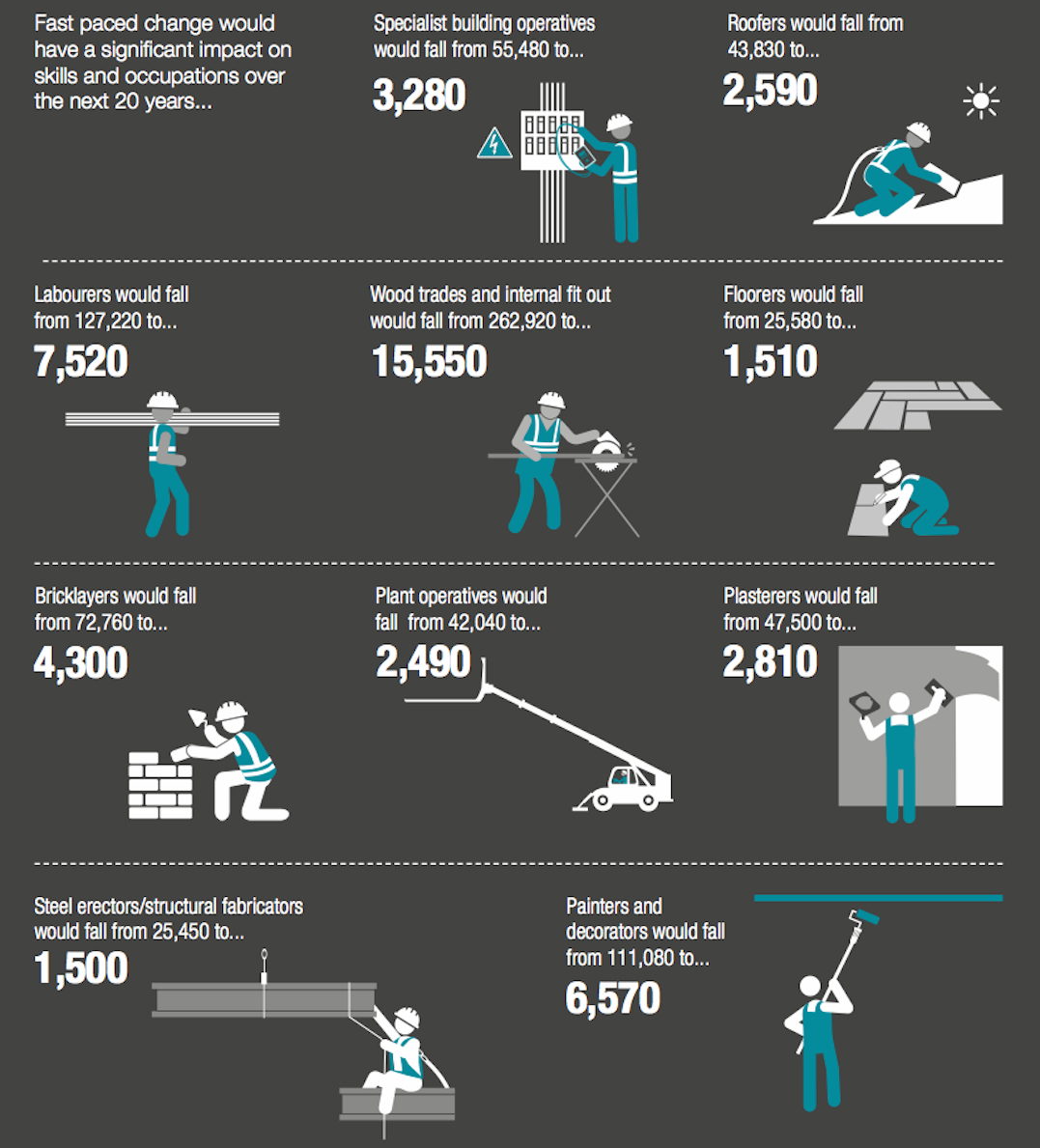

New techniques and technology could make up to 600,000 people in the UK construction sector redundant in the next two decades – more than a quarter of the current workforce – says the contractor and construction manager Mace.

Many thousands of bricklayers, painters and plasters would be replaced by robots or have their functions superseded by entirely new processes, radically altering the shape of a sector than now employs 2.3 million according to official figures.

Its report released yesterday says the next industrial revolution will transform the sector but that thousands of workers will need to be retrained to keep up with the pace of change.

Moving to Industry 4.0: A skills revolution also says UK construction could deliver an extra £25bn annually to the UK economy by 2040, but only if its glaring productivity gap is closed, reports Construction Manager.

“Artificial intelligence, robotics, the Internet of Things, autonomous vehicles, 3D printing and nanotechnology are going to completely transform the business and consumer landscape,” the report says.

The report argues that the figures – although only projections – give a sense of the scale of the talent pool that will need to be reskilled to allow the construction sector to move to Industry 4.0 and embrace productivity-improving technologies.

Mace warns that without a major effort to reskill the current workforce and attract a new generation of more tech savvy workers, the construction industry and the UK will lose out on the potential productivity benefits of the next industrial revolution.

Construction has long suffered from a productivity gap, where it has failed to match the productivity gains seen in other UK industries.

Estimates of personnel reductions under the fastest evolution scenario (Mace Group)

Improving productivity in the sector would also have a knock-on effect on UK housebuilding and infrastructure delivery, helping to alleviate the housing shortage and ensuring that major infrastructure projects are more likely to be delivered on-time and within budget.

Mace’s report proposes three key recommendations that will help to ensure that the necessary number of workers can be retrained:

1. Accelerate the use of new technology in training

By mandating that the latest 3D printing technologies and augmented and virtual reality tools are introduced into industry training programmes and into “construction clubs” in schools, the sector can better meet its future skills challenges while also ensuring that courses are attractive to potential students and recruits.

2. Inform lifelong learning decisions

At the moment data is sparse on what skills we will need in the future. By commissioning large-scale sector-wide research and working with government bodies such as the ONS and CITB, the construction industry will be able to ensure that its skills profile is changing to meet actual need.

3. Revolutionise our traditional education programmes

Current apprenticeship and training reforms will not go far enough to prepare the workforce for Industry 4.0. We need to upend the curriculum on offer now to reflect the modern methods of construction and offsite assembly that will be needed in the future.

Mace has placed innovation, research and investment in skills development at the centre of its business strategy. In 2016, the company invested £42m in research and development alone. This has included the development of industry-leading construction techniques, such as the “jump factories” being used by Mace on the construction of its East Village project in Stratford, London.

Mark Reynolds, chief executive at Mace, and skills lead on the Construction Leadership Council, said: “Everyone now acknowledges the current skills shortages need to be addressed. Our latest report highlights the opportunities the digital revolution can offer, how we can dramatically close the future skills gap and how we can meet the £25bn ‘productivity challenge’.

“The recommendations we have laid out will go some way towards addressing these issues. The industry, our training bodies and government need to work together to take full advantage of everything that Industry 4.0 can offer.”

See the report here.

Top image: A prototype printing robot climbs the wall of a test structure at Barcelona’s Institute for Advanced Architecture of Catalonia, as GCR reported here

Comments

Comments are closed.

In all the examples above the reduction in workforce for each one is about 94%. This seems very questionable and simplistic which throws the whole report into doubt.