Industrial conglomerate ThyssenKrupp has unveiled Multi, the world’s first ropeless elevator system.

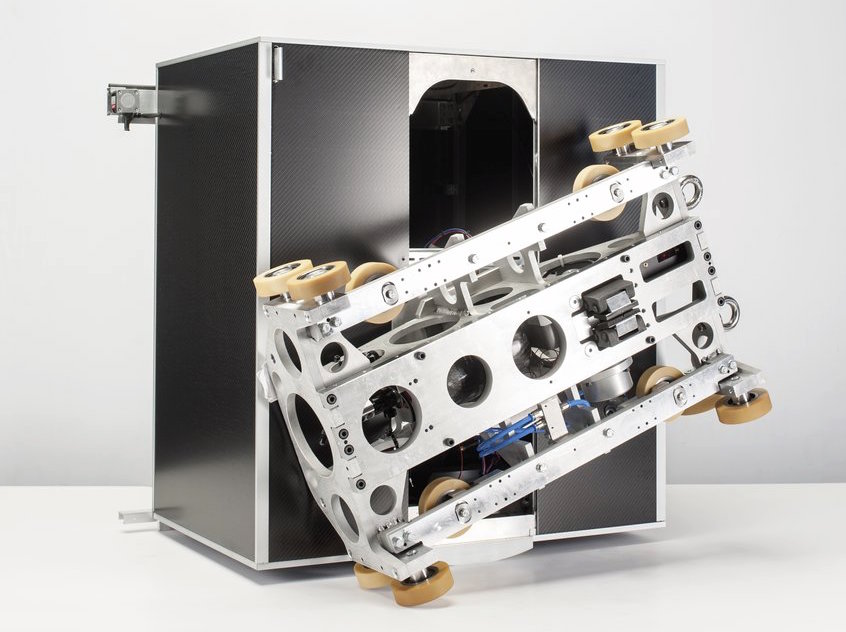

The fully functional, one-third scale model that was shown to the press this week uses linear induction motors based on magnetic levitation technology. These enable cabs to move sideways as well as vertically, thereby creating “vertical metro systems”.

According to ThyssenKrupp, the technology increases transport capacity and efficiency while reducing the elevator’s footprint and power consumption. It says the system requires smaller shafts than conventional elevators and can increase a building’s usable area by up to 25%.

Current elevator and escalator footprints can occupy up to 40% of a building’s floor space, depending on the buildings height.

Andreas Schierenbeck, chief executive of ThyssenKrupp Elevator, said: “As the nature of building construction evolves, it is also necessary to adapt elevator systems to better suit the requirements of buildings and high volumes of passengers.”

The elevator is currently in ThyssenKrupp’s Innovation Center in Gijón, Spain.

Images via ThyssenKrupp

Comments

Comments are closed.

You may not know you are on one except for the smoother ride. Like assembly moving magnets, elevator linear motors take up less space, have better control, & use less power.

II’m missing something here, but how is power consumption reduced when there is no counterweight?

Very interesting, the only thing that springs to mind is that it is electro magnetic, which means it needs electricity to work ! What happens it its supply is cut off ?

Presume most of the linear track is prefabricated and engineering off site, cost and delivery periods should be significantly improved, notwithstanding additional backup power requirements.

Not sure claims of current elevators and escalators occupying 40% of a building foot print are debatable?

Always good to see new technology emerging from a traditionally constrained M&E discipline.

Mark, when power supply is cut off, the brakes are automaticly set on.

Mark,

I’d imagine a system could be developed whereby power to a set of brakes would detach them from the braking surface, until power is lost and the brakes are therefore activated. Of course the use of relays etc could be used to reduce energy consumption and consideration should be made the the abrupt response of such system with power loss. However for the minds that have created this multi-directional elevator this should be a relatively simple task.

In the few pictures I don’t see counterweight. How it is possible this elevator consume less power than elevator with counterweight ?

We have elevator with efficiency 60%–80% with counterweight to have the same without, You must have efficiency greater than 1.

The advantage could be less space and the possibility to have vertical and horizontal movement.