The use of 3D printing in lightweight high-stress engineering roles has taken a step forward with its employment on Airbus’ latest passenger jet.

The 350 XWB twin-engine jet, which entered service with Qatar Airways in January, contains more than 1,000 components made using 3D printing technology. Â

Stratasys, the company that manufactured the parts, said the technique reduced production time and costs, and helped Airbus to meet its delivery deadlines. Â

Dan Yalon, vice president of Stratasys, said: “We’re delighted that Stratasys additive manufacturing solutions are being adopted by Airbus for its flagship A350 XWB aircraft. Â

“Both companies share a vision of applying innovative technologies to design and manufacturing to create game-changing benefits.”

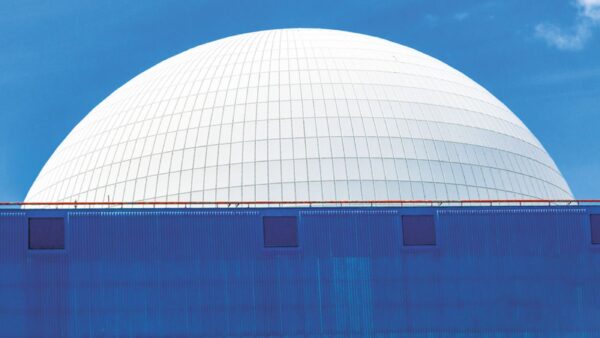

An Airbus 350 XWB (Stratasys)

James Woodcock, an expert on 3D printing with Rapid News, said: “From what I can gather it’s certainly unprecedented in scale.Â

“Historically, the use of 3D printed parts have been in military aircraft rather than commercial passenger jets.”Â

Stratasys is also contributing to a rocket due to launch next year.