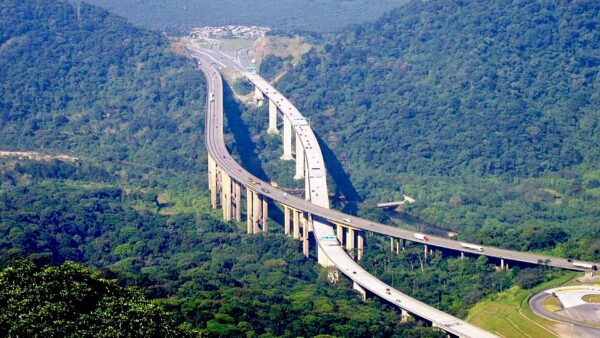

Dutch heavy lift specialist Mammoet has completed a tricky operation to replace a century-old rail bridge over the Hackensack River in the New York metropolitan area.

The company worked with contractors Skanska, Indiana-based Traylor, and local company Carver Marine to get three large sections of the new Portal North Bridge down the river and lifted into place.

The bridge connecting Newark, New Jersey, to New York City had become a notorious bottleneck owing to its decaying swing mechanism, which frequently malfunctioned and reduced speed to 60mph.

The line it is on is reckoned to be the busiest in the Western Hemisphere, with a train crossing every two minutes, carrying up to 200,000 passengers a day.

River transit

Mammoet transported three 120m-long sections from the assembly site at the Port of Coeymans to a location where they could be loaded onto a barge for transit down the Hudson River.

Mammoet said each section was loaded onto a mid-river stage before being transferred onto another barge prepared with Mammoet’s Mega Jack system.

Once on this, teams jacked each of the bridge sections to a height where they could be positioned using tugboats and winches before being lowered onto their support columns.

The two side sections had to undergo the additional step of being slid into place using the company’s slide track systems.

No swing needed

The new bridge will be 15m high, which does away with the need for a mechanical element to accommodate shipping. The span it replaces was only 7m above the Hackensack at high tide.

“The bridge section’s relocation and successful loading onto the barge demanded careful planning and close coordination with Skanska and Carver, and we’re proud to report a seamless operation,” said Mammoet project manager Sidney King.

• Subscribe here to get stories about construction around the world in your inbox three times a week

Further reading

Comments

Comments are closed.

That’s NJT for you….. pre-GREAT WAR/WW1 equipment being used in the 21st century yet NJ collects massive amounts of taxes and fares from the people but this is what they have to show for it.