Indian contractor Larsen & Toubro (L&T) announced on Tuesday, 30 June that it had completed work on its contribution to the ITER fusion reactor – the largest high-vacuum pressure chamber ever built.

The immense stainless-steel cylinder, which weighs 650 tonnes and measures 30m in height and diameter, will house the largest of the liquid helium-filled magnets that create the reactor’s torus.

To enable the magnets to operate with maximal efficiency, they are cooled to -193°C, a little above the boiling point of nitrogen.

The vacuum will help to maintain this temperature despite its nearness to hydrogen plasma heated to 150,000,000°C, around 10 times greater than the temperature at the core of the sun.

The completion of the project was marked by a virtual ceremony at L&T Heavy Engineering’s Hazira manufacturing plant in Gujarat, where the cryostat was assembled over six years.

Addressing the event, SN Subrahmanyan, the chief executive of L&T, said the company had used innovative and digital manufacturing techniques to ensure uninterrupted supply of high quality, high-precision assemblies.

He added that it was a milestone in the “Made in India” drive by helping the country to “acquire knowledge in this highly specialised field of science and technology”.

A particular difficulty that L&T had to overcome was that the cryostat has around 280 perforations, some of which are as large as 4m. These allow access for pipes, electricity, heating, diagnostics and remote handling systems, and each opening has to be leak-tight to preserve the cryostat’s vacuum, which is about 1 million times less dense than the Earth’s atmosphere.

The pressure chamber will form the final element in the cryostat assembly. L&T has already delivered its base section, the lower cylinder and the upper cylinder. These will now be welded together at ITER’s site at Cadarache, in the south of France.

The ITER reactor, which is expected to cost $19bn to build, is using equipment built around the world. European countries are responsible for 46% of the construction costs; the remainder is shared equally by China, India, Japan, Korea, Russia and the US. These countries will deliver 90% of their contribution in the form of completed components, systems or buildings.

The ITER team hope to achieve first plasma in December 2025.

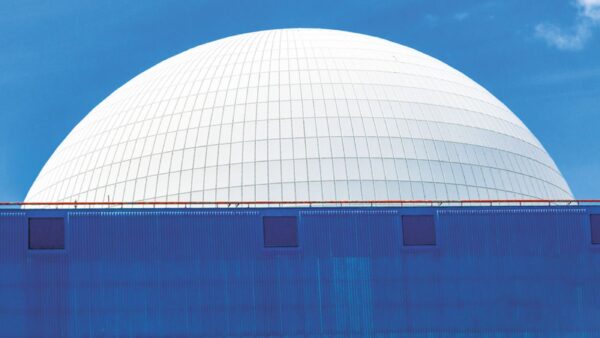

Image: L&T at work on the cryostat earlier this year (ITER)

Further reading: