Researchers at Washington State University (WSU) have discovered that adding charcoal to cement can result in a concrete that absorbs more carbon than is created by its production thanks to chemical reactions in the setting process.

They infused normal cement with “biochar”, a type of charcoal made from organic waste that has been soaked in concrete wastewater.

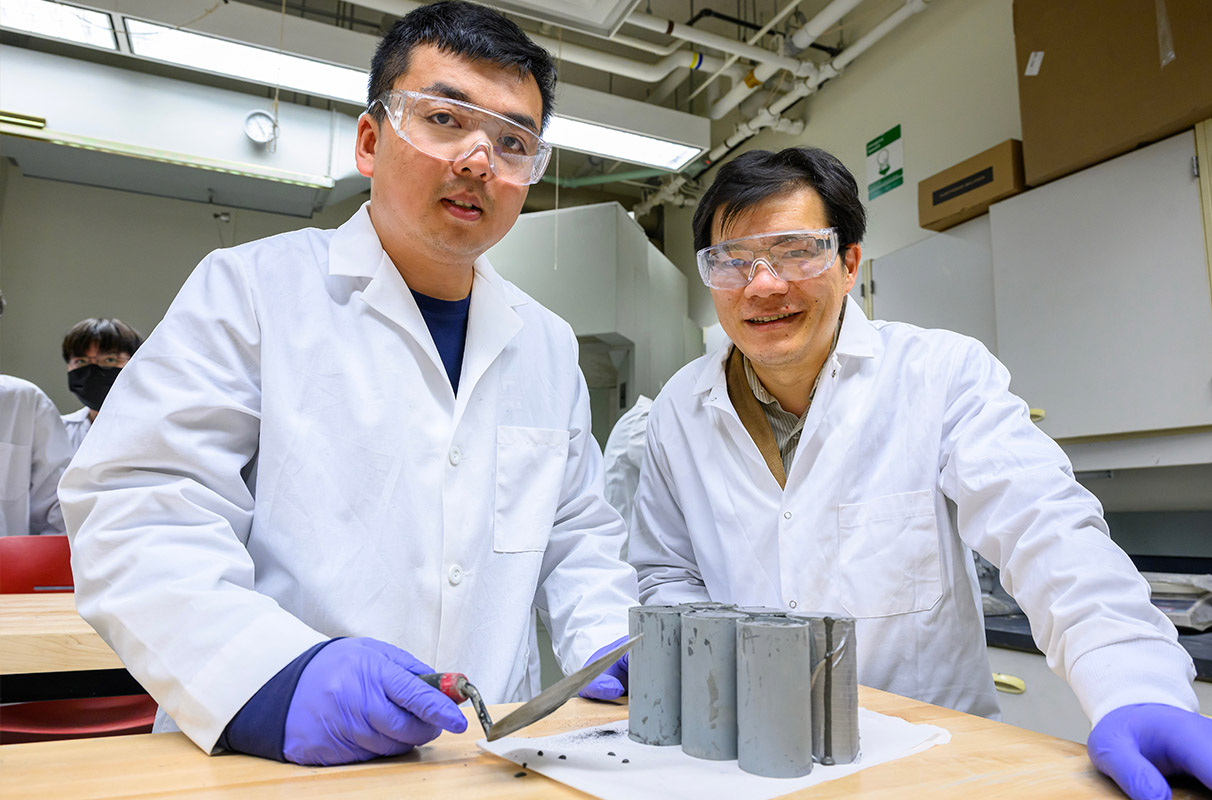

Led by doctoral student Zhipeng Li, the team found that the additive was able to absorb as much as 23% of its weight in carbon dioxide without degrading the load-bearing capacity of the resultant concrete.

The use of wastewater turned out to be the breakthrough for the concept. The water is high in calcium, which forms calcite, a stable polymorph of calcium carbonate, which changes the way the biochar interacts with the cement.

The team’s early experiments found that adding even small amounts of biochar to the cement dramatically reduced the strength of the concrete. However, the treatment with concrete “washout” water allowed as much as 30% of the cement mixture to be biochar and still achieve a compressive strength of about 4,000 pounds per square inch, equivalent to conventional concrete.

Xianming Shi, a professor in the WSU’s Department of Civil and Environmental Engineering, said: “We’re very excited that this will contribute to the mission of a zero-carbon built environment.”

Something like 8% of total carbon emitted as a result of human activity is thought to be caused by cement making and concrete production. This occurs because of the intensity of the energy needed to make cement, and chemical reactions in calcium carbonate when it is mixed with water to make concrete.

Professor Shi commented: “We’re committed to finding novel ways to divert waste streams to beneficial uses in concrete; once we identify those waste streams, the next step is to see how we can wave the magic wand of chemistry and turn them into a resource.”

“The trick is really in the interfacial engineering – how you engineer the interfaces in the concrete.”

The researchers received a seed grant from the Washington Research Foundation to produce data on how the concrete can be used. They are also seeking industry partners to scale up production for field demonstrations.

The results of the team’s work have been reported in the journal Materials Letters.

Further reading: