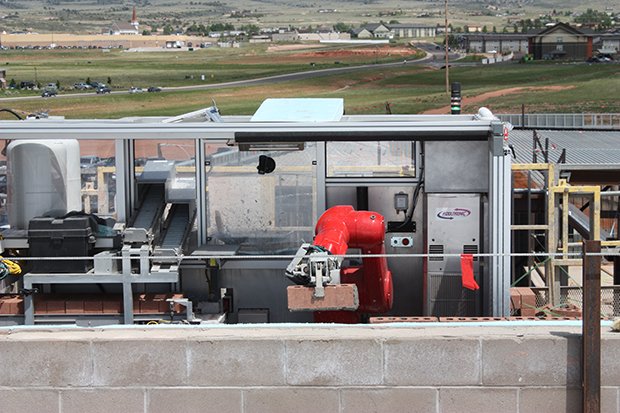

New York firm Construction Robotics has created SAM, the world’s first commercially available bricklaying robot.

The unit, which has a retail price of $500,000, works alongside a human tradesperson. Together, they can lay up to four times the number of bricks than a man could when working alone.

SAM (it stands for semi-automated mason) works best on long stretches of wall and can create complex patterns using different brick types.

The robot has been in development for eight years and has been trialled at multiple construction sites in the US.

Our sister site, Construction Manager, quoted Zachary Podkaminer, operations manager at Construction Robotics, as saying: “SAM is now commercially available. We are building two more units right now that will be available to purchase in two weeks.

“Of course, SAM will continue to be improved, but we are finally at a stage where she is working very effectively and efficiently.”

Podkaminer said SAM would not yet replace bricklayers: “Your mason monitors wall quality, while SAM does the heavy lifting. Masons that haven’t worked with SAM are hesitant at first, but once they learn and work with the robot and realise it won’t take their job they are very open to it.”

SAM is controlled and operated wirelessly, and uses a laser sensor that corrects for any movements that may knock her off course.

Podkaminer predicts that there will be a demand for robots like SAM, as there is a lack of skilled bricklayers in the global construction industry.

In other robonews, a deconstruction robot that munches on concrete was used on construction sites in 2013, last year researchers in Spain used wall-climbing mini-bots on 3D printed buildings and this year an Australian inventor created Hadrian, a brickbot that “can build a house in two days”.

Images via Construction Robotics amd YouTube

Comments

Comments are closed.

t’s really cool that they have come up with a robot that can do these kinds of things proficiently, but I don’t know if it’s as good as human. Even though the machine is able to do this process fast, it’s not the same as the job a real mason could do. I really think that there is real beauty in the the small mistakes that humans can make.

I am a 60 year old bricklayer. I would like to see these robots see if it could tell if the brick Is a bit long say 2 mill or 1 mill we in the trade can make it work so you don’t go over the gross joint